Ice Cream

Practical Action

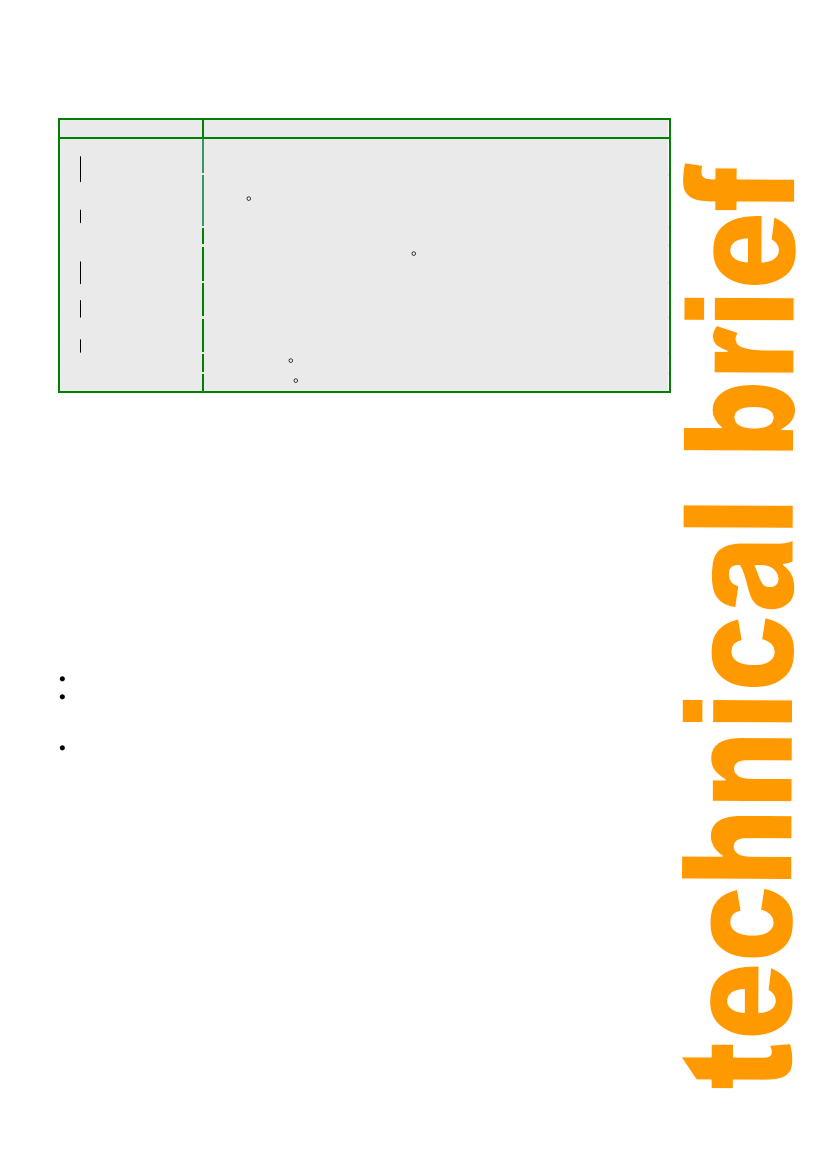

Stage in process

Weigh

Notes

Premix dry ingredients with 3 or 4 times their weight of sugar. Weigh all

main ingredients, except fat, into pasteurisation vessel.

Heat

To 50 C and add any solid fats.

Pasteurise

Cool

Freeze and aerate

Pack

At 65°C for 30 minutes or 72°C for 10 minutes with thorough mixing.

For a minimum of 4 hours at 3-5 C to allow fats to crystallise and the

viscosity to increase.

Using an ice cream machine to reduce the temperature to –5°C as quickly

as possible.

Fill into pots or cardboard cartons.

Harden

At below -20 C

Cold store

At –18 to -20 C

Figure 1: Method of ice cream production

Equipment

Pasteuriser

A pasteuriser is used to heat the ice cream mixture. At a micro-scale of production, a stainless

steel pan (or less desirably an aluminium pan) is heated with constant stirring to prevent the

mixture overheating or burning at the base of the pan. At small- and medium-scale production, a

jacketed stainless steel pan (see Technical Brief Pasteurised milk) gives better control over

heating. Steam from a boiler heats the space between the outer jacket and inner pan to give

more uniform heating and avoid localised burning of the product. It may be fitted with an

agitator.

Ice Cream Freezers

Small manual or electric ice cream makers have a stainless steel bowl that is frozen by one of

three methods:

the bowl is immersed in a freezing liquid (e.g. an ice/salt mixture).

a double-walled bowl is placed in a freezer, and the salt/ice between the bowl walls is

frozen (the bowl needs to be refrozen for the next batch). Typically, both can freeze ice

cream within 15 - 20 minutes.

the bowl is surrounded by refrigeration coils that are built into the machine (Figure 2).

Some machines also have a built-in pasteuriser.

Other designs (Figure 3) pump the ice cream mixture to freeze and aerate it. These types of

machines can produce ice cream continuously and may be used in retail outlets.

Each type of ice cream maker has a rotor that scrapes the frozen ice cream mixture from the

bowl wall and at the same time incorporates air. Freezing continues until the liquid is frozen at -

4 to -7°C. This soft ice cream is then either sold directly or hardened in a freezer at –18°C. At a

larger scale, more expensive continuous freezers that have capacities above 200 litres per hour

are used.

4